Auxilliary Water Heater - Part 1

Not completely successful, but proved the theory.

The Plan for the Heater

Cooler water from the bottom of the tank would enter the tubing at the bottom of the serpentine, be heated by the flue pipe and return to the top of the tank, heated. If the levels between the flue pipe and the tank are correct, this will take place by thermosiphon effect. In my '88 Westfalia, the sink water comes from an outlet near the bottom of the tank. However, I discovered that in an '89, the in-tank pump pumps water out the top of the tank. If things do not line up, a small circulating pump will be installed.

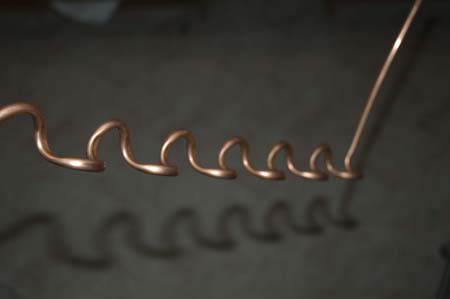

Bending the Tube

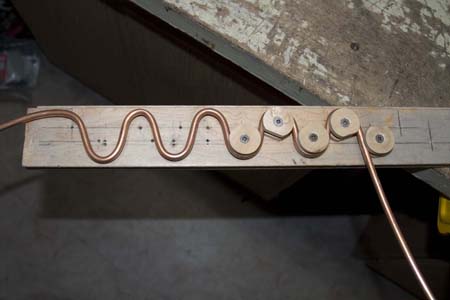

Curving the Serpentine

With an armature press, a 3/4" steel bar, the same diameter as the flue pipe, pressed the serpentine of copper tubing into another jig (also of scrap maple flooring) with a 1 1/4" diameter concave shape in it.

The Curved Serpentine

All bent, curved and ready to install. The result uses nearly 42" of tubing within 14" of length. The nearly semi-circular shape was used because the tubing could not be wrapped completely around the flue pipe. The 12V and 120V heater elements, as well as the ammonia boiling tube are bonded to the flue pipe for the lower 1/4 of its length. As well, installing it would mean removing the brass ferrule and flexible flue.

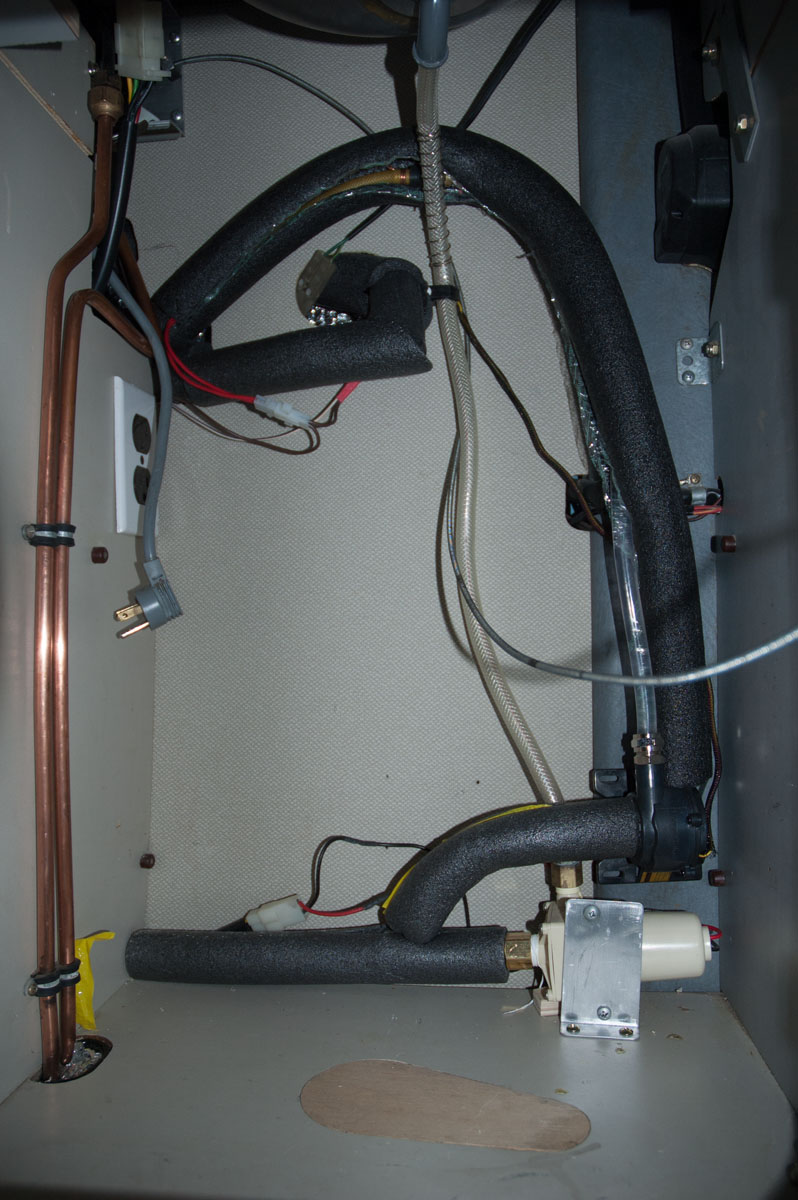

Fitted to the Dometic

The copper tube serpentine has been fitted to the flue, tied with wire so it is in direct contact with the flue pipe.

At the moment there is 6' of 3/8" plastic hose on the inlet and another 6' on the return side of the heating tube. This length is greater than the distance between the fridge and the water tank when properly installed in the Westfalia.

The Test Setup

With a fridge, propane bottle, battery and water tank (from an '89), testing takes place.

In the first test a 1 liter water tank was used. By thermosiphon action, the temperature of the water was raised from 13oC to 53oC in 5 hours. Meanwhile the fridge was chilling the beer!

However when the experiment was enlarged to using the Westfalia tank, thermosiphon effect would not work! The storage was at the same height as the heater tube, so water would not circulate.

At this time neither the tank nor the plastic tubing is insulated, so probably loses a lot of heat in the transferring process.

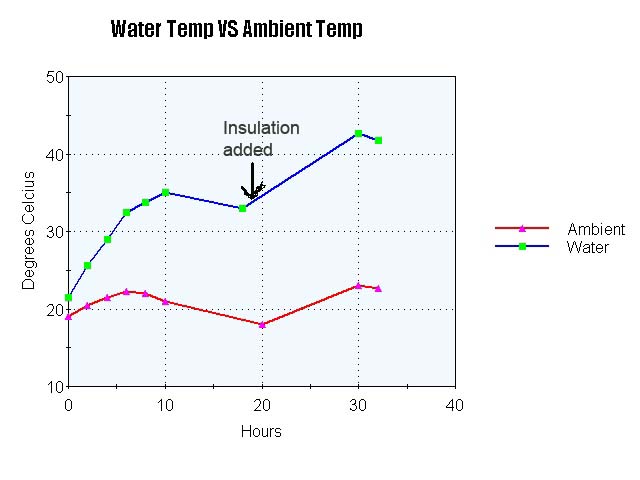

Graph of Results

The water temperature rose from 19 to 35oC in 11 hours, despite neither the tank nor the tubing being insulated.

Part way through the experiment the tank was insulated with a blanket, and the temperature rose to 42.6oC - which should be perfect for a shower.

For a final test, the tank was filled to the FULL indicator (about 39 litres of water) and left for 12 hours. It maintained around 40oC.

Since the aim of the project is to simply maintain the temperature of the stored water at around 42oC over night, after it has been heated by the vehicle's engine, this looks promising.